Mastering Supply chain Risk Assessment

A supply chain risk assessment is the process of identifying, analyzing, and mitigating potential vulnerabilities within your network of suppliers, manufacturers, and distributors. It's a proactive strategy to map out weaknesses before they disrupt your operations, ensuring your business runs smoothly no matter what challenges arise.

Why Your Supply Chain Is More Fragile Than You Think

Remember the global chip shortage that brought car manufacturing to a screeching halt? Or when a single container ship blocked the Suez Canal, causing a traffic jam that echoed across global trade? These incidents were stark reminders of how interconnected and fragile modern supply chains are.

In fact, a staggering 94% of Fortune 1000 companies have experienced a supply chain disruption. That number highlights a brittleness many businesses don't see until it's too late. This guide shifts the focus from reactive crisis management to proactive resilience. By conducting a thorough risk assessment, you can anticipate challenges and build a supply chain that doesn't just survive—it thrives.

The True Cost of Inaction

Ignoring supply chain risks is a direct threat to your bottom line. Major disruptions can cost large companies an average of $184 million in lost revenue annually. These financial hits are the result of cascading problems that a robust risk assessment helps you avoid.

Without a clear understanding of your supply chain, you leave your business vulnerable to:

- Production Halts: A single missing part from one supplier can shut down an entire assembly line, leading to expensive downtime and missed deadlines.

- Damaged Customer Trust: Failing to deliver on time breaks promises. Research shows that 84% of customers will not return after just one poor delivery experience.

- Reputational Harm: Being linked to unreliable suppliers or unethical labor practices can inflict immediate and lasting damage on your brand.

Building a Competitive Advantage Through Resilience

A proactive approach to supply chain risk creates a powerful competitive edge. By identifying and strengthening your weak points, you build a more robust and agile operation.

For example, gaining tighter control over the flow of goods and people through your facilities provides a significant advantage. Optimizing how deliveries are received and personnel move eliminates bottlenecks and security gaps—both common sources of risk. You can explore the benefits of a delivery management system to learn how this oversight strengthens your entire logistics chain.

A resilient supply chain isn’t just a defensive play; it’s a strategic asset. Companies that master risk assessment bounce back from disruptions faster, often capturing market share from less prepared competitors.

Ultimately, this process turns uncertainty into an advantage. By anticipating shocks, you protect your revenue, maintain customer loyalty, and build a supply chain that thrives under pressure.

Understanding the Anatomy of Supply Chain Risk

To manage risk effectively, you must first understand its different forms. "Risk" can feel like a vague threat, but it's a collection of specific, tangible issues you can identify, measure, and control.

A geopolitical flare-up isn't just a headline; it's a sudden border closure that traps your shipment. A key supplier facing financial trouble isn't just a report; it's a critical component suddenly becoming unavailable. A proper supply chain risk assessment helps you dissect these threats and pinpoint your most fragile links.

The Primary Categories of Risk

Supply chain risks fall into predictable categories. According to the WTW Global Supply Chain Risk Survey, business priorities have evolved dramatically. Concern over health and pandemic risks has dropped from 23% to 13%, while geopolitical instability, cyber threats, and fragile supplier relationships have surged to the forefront. This shift indicates where businesses feel the most pressure today.

"A risk is a risk, regardless of its source. The real challenge isn’t just identifying individual threats, but understanding how they connect and create a domino effect across your entire value chain."

Let's break down the main types of risk you'll encounter.

Deconstructing Your Vulnerabilities

Each category of risk has a unique signature and impact. From a fire in a single factory to a sudden shift in consumer demand, knowing what to look for is half the battle.

Here’s a quick look at the main types of risk, where they originate, and the damage they can cause.

Key Categories of Supply Chain Risk

| Risk Category | Description & Examples | Potential Impact on Business |

|---|---|---|

| Operational Risks | Internal issues that disrupt daily activities, such as equipment breakdowns, IT system failures, warehouse accidents, or labor shortages. | Production halts, increased operational costs, and safety incidents can lead to complete shutdowns. |

| Financial Risks | Monetary threats, including sudden price spikes for raw materials, currency fluctuations, or a key supplier declaring bankruptcy. | Reduced profitability, cash flow shortages, and difficulty funding new orders or securing financing. |

| External Risks | Large-scale, often unpredictable events like natural disasters, political conflicts, new tariffs, or major cyberattacks. | Severed logistics routes, loss of inventory and facilities, and market chaos. |

| Compliance & Legal | Risks arising from new regulations and legal disputes, such as environmental laws, labor issues, customs delays, or safety standard violations. | Heavy fines, litigation, seized shipments, and loss of operating licenses. |

For most businesses, operational risks are the most immediate and controllable. For example, in industries dealing with fresh food or pharmaceuticals, a simple refrigeration failure is a massive threat. Proper cargo risk management for temperature-sensitive goods is essential.

Similarly, managing operational risk involves ensuring every person on your site—from contractors to drivers—adheres to safety protocols. A formal manufacturing safety audit checklist helps standardize this process. This is where a visitor management system provides a clear benefit: it ensures every individual is checked in, inducted, and accounted for, giving you the peace of mind that your facility is secure and your safety protocols are being followed.

Your Step-By-Step Risk Assessment Framework

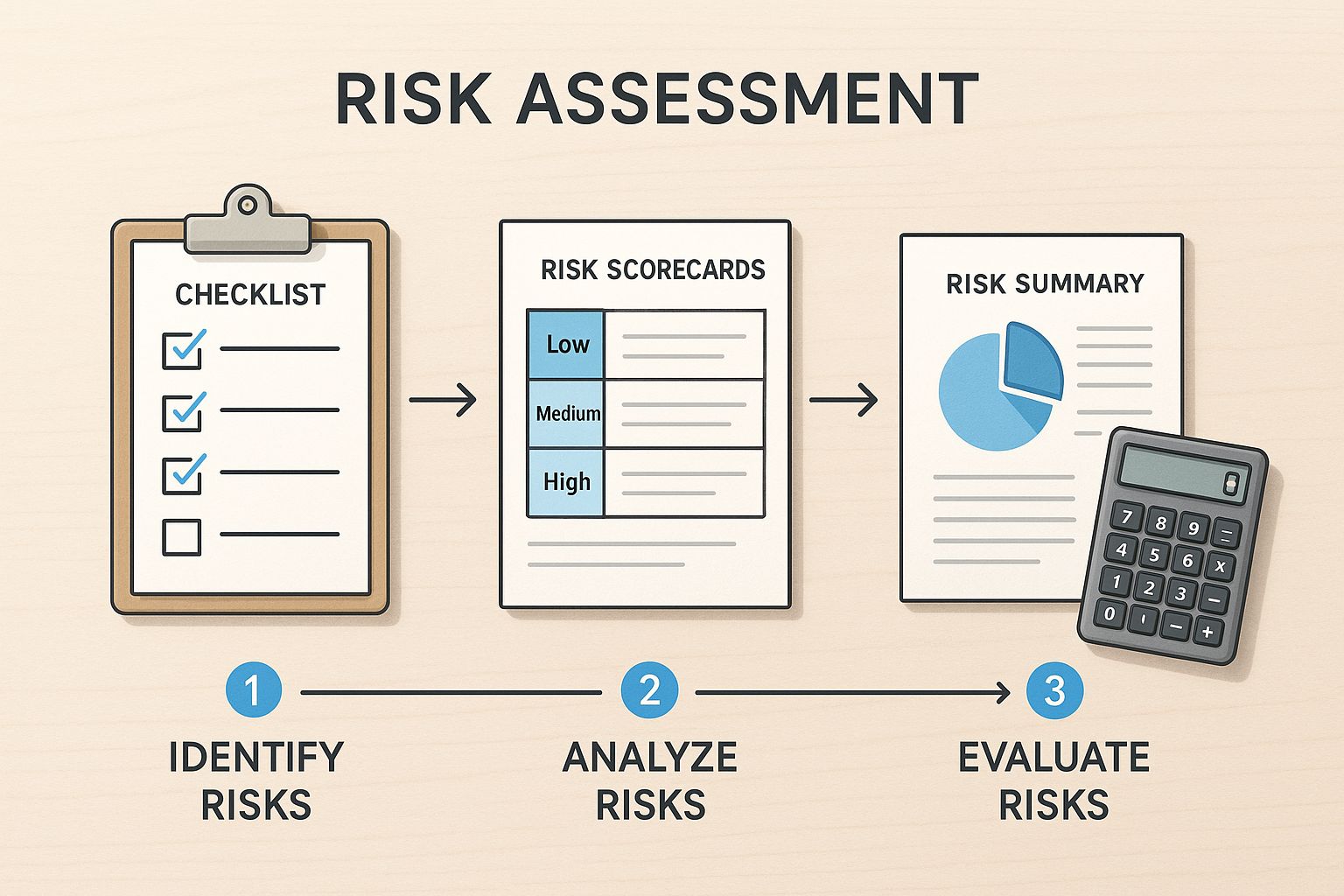

A structured supply chain risk assessment is a practical, repeatable process for building resilience into your operations. Think of it as a routine health check-up for your entire network.

This framework breaks the process into five clear stages. Following these steps will shift your approach from worrying about disruptions to methodically building a supply chain that can withstand them.

A successful risk assessment isn't a one-time event. It's a continuous, data-driven journey of analysis and refinement.

Step 1: Identify and Map Your Supply Chain

You can't protect what you can't see. The first step is to create a detailed map of your entire supply chain, from raw material suppliers (Tier 2 and 3) to the end customer. It's shocking, but studies show that nearly 50% of companies lack full visibility into their extended supply networks. This lack of visibility is a massive blind spot where disruptions can originate.

Your goal is to pinpoint every critical node and link:

- Key Suppliers: Who provides your most critical components?

- Manufacturing Sites: Where are your products made or assembled?

- Logistics Hubs: Which warehouses and distribution centers are essential?

- Transportation Routes: What are the primary shipping lanes you depend on?

The act of mapping often uncovers hidden dependencies and single points of failure you never knew existed.

Step 2: Analyze and Prioritize Potential Risks

Once your supply chain is mapped, brainstorm everything that could go wrong at each point. You can't fix everything at once, so prioritization is key. An effective tool for this is the risk matrix, which scores each threat based on two factors:

- Likelihood: How probable is it that this event will occur?

- Impact: If it does occur, how severe will the damage be?

Plotting risks on this matrix helps you focus on high-likelihood, high-impact threats, ensuring your resources are allocated effectively.

Step 3: Develop Mitigation Strategies

With your biggest risks identified, it’s time to build a defense plan. Mitigation strategies fall into two categories: proactive and reactive.

- Proactive Strategies: Actions taken before a disruption to prevent it or lessen its impact, such as diversifying your supplier base or pre-qualifying backup logistics partners.

- Reactive Strategies: Your emergency plan when a disruption occurs, such as holding strategic safety stock or having a crisis communication plan ready.

A solid plan includes both. For instance, a proactive step is implementing a strict visitor and contractor check-in process. The benefit isn't just a badge printer; it's the peace of mind that comes from knowing every person on your site is vetted and understands your safety rules, directly lowering your operational risk.

Step 4: Implement and Document Your Plans

A plan that exists only on paper is useless. Implementation involves turning strategies into action. Assign clear owners for each mitigation plan, secure the necessary resources, and train your team.

A documented plan is a resilient one. It ensures that knowledge isn’t siloed with one or two key employees but is embedded into your organization's institutional memory.

Clear documentation is non-negotiable. It must outline specific steps, responsibilities, and activation protocols, turning your strategy into an executable playbook for times of crisis.

Step 5: Monitor, Review, and Refine

Risk is never static. Geopolitical situations evolve, new regulations emerge, and your suppliers' financial health can change overnight. A risk assessment becomes outdated almost immediately if not reviewed.

Effective risk management is a continuous cycle. Set up key performance indicators (KPIs) to track your mitigation plans. Review your risk matrix regularly—at least annually, or after any major disruption—to see if priorities have shifted. This feedback loop helps you learn, adapt, and continually strengthen your resilience.

Using Technology for a Clearer View of Your Supply Chain

Modern supply chain risk assessment runs on data, not guesswork. Relying on spreadsheets and manual processes is like driving in fog without headlights—you can't see dangers until it's too late. Technology transforms risk management into a real-time, proactive process.

The industry is moving fast in this direction. A recent study revealed that 82% of supply chain organizations have increased their IT budgets to focus on digital tools, AI, and automation. This trend shows that advanced technology is now essential for managing risk.

Getting Ahead of Problems with AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) analyze vast amounts of data—from sales history and weather forecasts to social media trends—to identify patterns that a human analyst would miss.

The benefit is predictive insight. AI can sharpen demand forecasting to prevent stockouts or overstock situations. It can also run "what-if" simulations to show how a factory shutdown in one region could impact your production schedule weeks later, enabling data-driven decisions.

AI is the difference between hearing about a traffic jam when you're already stuck in it versus your GPS warning you miles ahead so you can take another route. It turns historical data into a roadmap for the future.

Seeing Everything in Real-Time with IoT

The Internet of Things (IoT) provides a live feed of your goods in transit. Sensors on containers, pallets, or trucks stream constant updates on location, temperature, humidity, and more.

This live information creates unprecedented transparency:

- Condition Monitoring: Receive instant alerts if a temperature-sensitive shipment goes outside its safe zone, allowing you to intervene before the product is lost.

- Asset Tracking: Know the precise location of your inventory at all times, reducing theft risk and providing customers with accurate arrival times.

- Equipment Health: Predict when factory machinery is about to fail, enabling proactive maintenance before a breakdown halts production.

Bringing It All Together with Analytics and Cloud Platforms

Data from AI and IoT is most valuable when centralized. Analytics platforms and what is cloud-based software act as your mission control, pulling data from all sources into a single dashboard.

This bird's-eye view is essential for effective risk management. Instead of digging through siloed spreadsheets, you can instantly spot connections and vulnerabilities across your entire operation. A modern visitor management system is a critical piece of this technology puzzle. By digitally logging every person who enters your facilities, you gain complete control over site activity. The benefit is a secure and compliant environment where you have a clear record of who is on-site and can account for them in an emergency, strengthening your defenses from the front gate to the loading dock.

Integrating Sustainability Into Your Risk Strategy

A resilient supply chain and a sustainable one are now two sides of the same coin. Environmental, Social, and Governance (ESG) factors are a core part of any serious supply chain risk assessment. Ignoring them exposes your business to tangible, expensive threats.

A supplier with poor labor practices (a social risk) could spark a consumer boycott or attract regulatory fines. Partnering with a factory in a region facing severe water shortages (an environmental risk) creates a massive production vulnerability. These are not abstract concepts; they are real-world weak points.

The Growing Importance of ESG in Risk Management

The demand for ethical and sustainable supply chains is growing. Consumers, investors, and regulators expect transparency and accountability. In fact, a staggering 90% of S&P 500 companies now publish sustainability reports—a clear sign of its strategic importance.

Ignoring ESG is a gamble with both your brand and your operations. A strong ESG profile is a powerful defense mechanism.

By weaving ESG criteria into your supplier vetting process, you aren't just building a more ethical supply chain—you're building a more disruption-proof one. Suppliers with strong sustainability practices are often better managed and more resilient overall.

This shift is reflected in global data. Research shows that factors like environmental impact, human rights, ethics, and sustainable procurement are now mandatory components of risk assessment frameworks.

How to Integrate ESG Into Your Assessment

Integrating sustainability into your risk strategy requires a new lens for evaluating partners. You need to ask tougher, more holistic questions before signing a contract. For example, understanding the nuances of sustainability in the retail industry is critical, as these factors directly impact stability and risk.

Forward-thinking companies are taking these steps:

- Supplier Code of Conduct: Enforcing clear ESG standards for all suppliers, covering everything from fair labor to waste reduction.

- On-Site Audits: Conducting physical inspections to verify that on-the-ground practices match documented policies.

- Third-Party Certifications: Using recognized certifications (like Fair Trade or ISO 14001) to qualify new partners.

- Continuous Monitoring: Using technology to track media reports, NGO watchlists, and regulatory changes to spot emerging ESG risks.

Securing Your Brand and Your Bottom Line

Building sustainability into your operations protects your business from the inside out. Guaranteeing that every partner and contractor meets your ethical and safety standards drastically lowers the risk of reputational damage.

Here, a modern visitor management system provides a direct benefit. By requiring every third-party individual—from maintenance crews to delivery drivers—to complete a digital induction covering your specific ESG and safety rules, you create an auditable record of compliance. This system ensures everyone on your property understands your standards, turning policy into enforced practice and protecting your brand.

Building a Supply Chain That's Ready for Anything

If you take one thing away from this guide, let it be this: supply chain resilience is one of today's most powerful competitive advantages. A solid supply chain risk assessment is not an expense; it's an investment in business continuity, customer satisfaction, and sustainable growth.

The goal is to build a supply chain that can bend without breaking. Waiting for the next disruption is not an option. In fact, companies that master risk management can recover from a major event 50% faster than those who don't.

From Playing Defense to Going on Offense

A well-executed risk assessment process creates measurable value. Businesses that proactively manage risk see an average 5% reduction in operational costs and a 7% increase in customer satisfaction. These numbers prove that building resilience pays off.

When you can promise reliability no matter what is happening in the world, you build a level of trust that competitors can't match. This stability allows you to seize opportunities while others are focused on survival.

A strong risk management program flips the script from a defensive crouch to an offensive stance. You’re not just plugging holes; you're building the foundation to innovate and grow with confidence.

Your First Steps Toward a Resilient Future

The journey starts now. First, formalize your emergency plans. You can use an emergency response plan template to create a clear playbook for your teams, ensuring everyone knows what to do when a disruption hits.

At the same time, secure your physical locations. Knowing who is on your property is fundamental to risk management. A visitor management system provides that control, ensuring every person on-site is identified, screened, and accounted for. This benefit strengthens security and improves safety compliance, giving you peace of mind that your facilities are protected.

Ultimately, the aim is to create a culture that views risk not as a threat, but as a manageable variable. By putting these strategies into action, you're not just protecting your company—you're building a future-proof supply chain.

Common Questions About Supply Chain Risk Assessment

Getting started with a supply chain risk assessment can feel overwhelming. Here are answers to some of the most common questions.

How Often Should We Be Doing This?

Think of your risk assessment as a continuous cycle, not a one-time project. A full, deep-dive assessment should be conducted at least once a year.

However, you should also revisit it whenever significant changes occur, such as onboarding a major new supplier, expanding into a new region, or reacting to a major global event. The key is to keep the process dynamic and responsive.

What's the Single Biggest Mistake Companies Make?

The most common pitfall is focusing only on direct, Tier 1 suppliers. A staggering number of disruptions originate two, three, or even four levels down the chain with suppliers you may not even know you depend on.

Failing to map your entire network creates massive blind spots. Shocks that seem to come out of nowhere are often predictable if you have the visibility to see them coming.

Focusing only on your main suppliers is like checking the front door for security but leaving all the windows unlocked. The real threats often find their way in through these overlooked entry points.

Can a Small Business Really Pull This Off?

Absolutely. A supply chain risk assessment is scalable. You don't need a massive team or a huge budget to get started.

A smaller business can begin by identifying its most critical suppliers and biggest internal vulnerabilities. The core principles of identifying, analyzing, and mitigating risk work for businesses of all sizes. The key is to start small and build from there.

We Have a Tight Budget. Where Do We Even Begin?

With limited resources, start with what you can directly control: your own operations and immediate supplier relationships.

First, identify the few suppliers whose failure would halt your business. Then, turn your focus inward. A high-impact, low-cost starting point is improving the safety and security of your own facilities. For instance, implementing a visitor management system gives you the immediate benefit of controlling who is on your property. This secures your site and ensures every person—from contractors to drivers—is aware of your safety protocols, directly reducing operational risk without a large upfront investment.

A robust system like VisitUs puts the power back in your hands, helping you secure your sites, maintain compliance, and gain complete visibility over everyone on your premises. By automating check-ins, safety briefings, and emergency headcounts, you build a stronger first line of defense against operational threats. Find out more about how it works at the official VisitUs website.