How to Improve Operational Efficiency in Your Business

Improving operational efficiency isn’t just about slashing costs—it's about maximizing the value of the resources you already have.

The best strategies come down to a few core ideas: mapping processes to spot bottlenecks, using smart automation to empower your team, and tracking the right performance metrics to guide improvement. It all starts with understanding that small, targeted changes can create a massive positive impact across your entire company.

The True Cost of Inefficiency and How to Fix It

Soaring costs and clunky workflows are a direct threat to your company’s growth. Many businesses operate with hidden inefficiencies that bleed resources, delay projects, and burn out talented employees. The damage from these unseen problems is staggering.

The numbers prove it. Disengaged employees, often a result of frustrating processes, cost the global economy an estimated $8.9 trillion in lost GDP. That statistic from MyHours.com puts the need for smarter workflows and employee engagement into sharp perspective.

Operational efficiency is the art of achieving more with less—getting more output from the same input. It's about fine-tuning your business engine so that every resource, from your team's time to your technology budget, delivers maximum return.

Shifting from Cost-Cutting to Value Creation

It's a common mistake to see "efficiency" as just another word for "cost-cutting." While trimming waste is a benefit, the real goal is to create more value. This means empowering your team to ditch repetitive admin tasks and focus on high-impact work that drives growth.

When you dial in your operations, you unlock benefits that go far beyond the balance sheet:

- Higher Profitability: Streamlined processes allow you to deliver top-notch services at a lower cost, which goes straight to your bottom line.

- Improved Employee Morale: No one enjoys wrestling with broken workflows. Fixing them gives your team back their time for meaningful work, which is a massive win for retention.

- Greater Business Agility: Efficient companies can pivot quickly. With smooth workflows, you have the bandwidth to react to market shifts and seize new opportunities without missing a beat.

Here's a quick look at how the strategies in this guide fit together to deliver these results.

Your Roadmap to Operational Efficiency

This table breaks down the core pillars we'll be covering, what each one aims to achieve, and the tangible benefits you can expect to see in your business.

| Strategy Pillar | Core Objective | Key Business Benefit |

|---|---|---|

| Process Mapping & Analysis | To visualize and understand current workflows, identifying bottlenecks, redundancies, and areas for improvement. | Reduced waste, clearer role responsibilities, and a foundation for targeted optimization. |

| Smart Automation | To automate repetitive, manual tasks, freeing up employees for more strategic and high-value work. | Increased productivity, lower error rates, and improved employee morale. |

| KPI & Performance Tracking | To measure what matters by tracking key performance indicators that align with business goals. | Data-driven decision-making, continuous improvement, and better resource allocation. |

Think of this as your high-level map. We'll dive into the specifics of each pillar, giving you actionable steps to start making changes right away.

A Roadmap to Smarter Operations

This guide provides a clear path to transform your operations with practical, step-by-step strategies. A great, and often overlooked, place to start is your front desk, where every first impression is made.

A modern visitor management system, for example, is the perfect catalyst for change. Automating guest check-ins, instantly notifying hosts of arrivals, and tightening security all free up your front-desk staff for more important duties. This single change can set a new standard for efficiency that echoes throughout your entire company. Let’s walk through the core pillars to get you these kinds of results.

Visualize Your Workflows to Uncover Bottlenecks

You can't fix a problem you can't see. Before making any meaningful improvements, you need a crystal-clear picture of how work actually gets done in your organization.

This is where process mapping comes in. Think of it as creating a simple, visual roadmap of your business operations. By sketching out each step, you immediately start to see the hidden friction points, redundant tasks, and communication breakdowns that quietly drain your resources.

These are the bottlenecks that frustrate employees and slow down growth.

The Power of Making Processes Visible

When you put a workflow on paper, abstract problems become concrete and solvable. There's a reason for this: a study found that businesses using process management techniques can improve project success rates by as much as 75%. It turns guesswork into a data-informed strategy.

For example, a manufacturing firm might map its production line and discover a consistent three-hour delay during quality assurance checks, all due to paperwork not being ready. In an office, you might find the visitor sign-in process involves three different people entering the same guest information into separate systems—a clear waste of time and a recipe for errors.

These are the powerful insights that only come from making things visible.

Simple Tools for Uncovering Inefficiencies

Getting started with process mapping doesn’t require expensive software. The real focus should be on clarity and team involvement. Here are a few practical ways to start visualizing your workflows:

- Basic Flowcharts: Simple shapes and arrows are all you need to outline a process, perfect for spotting decision points and potential delays.

- Swimlane Diagrams: This type of flowchart organizes tasks into "lanes" for each team, making it incredibly effective at highlighting clumsy handoffs.

- Value Stream Mapping: A more advanced technique that looks at the flow of materials and information, helping you separate value-adding activities from wasteful steps.

To really dig into bottlenecks, it helps to see how others improve warehouse efficiency effectively, as logistics is often a critical part of the operational chain.

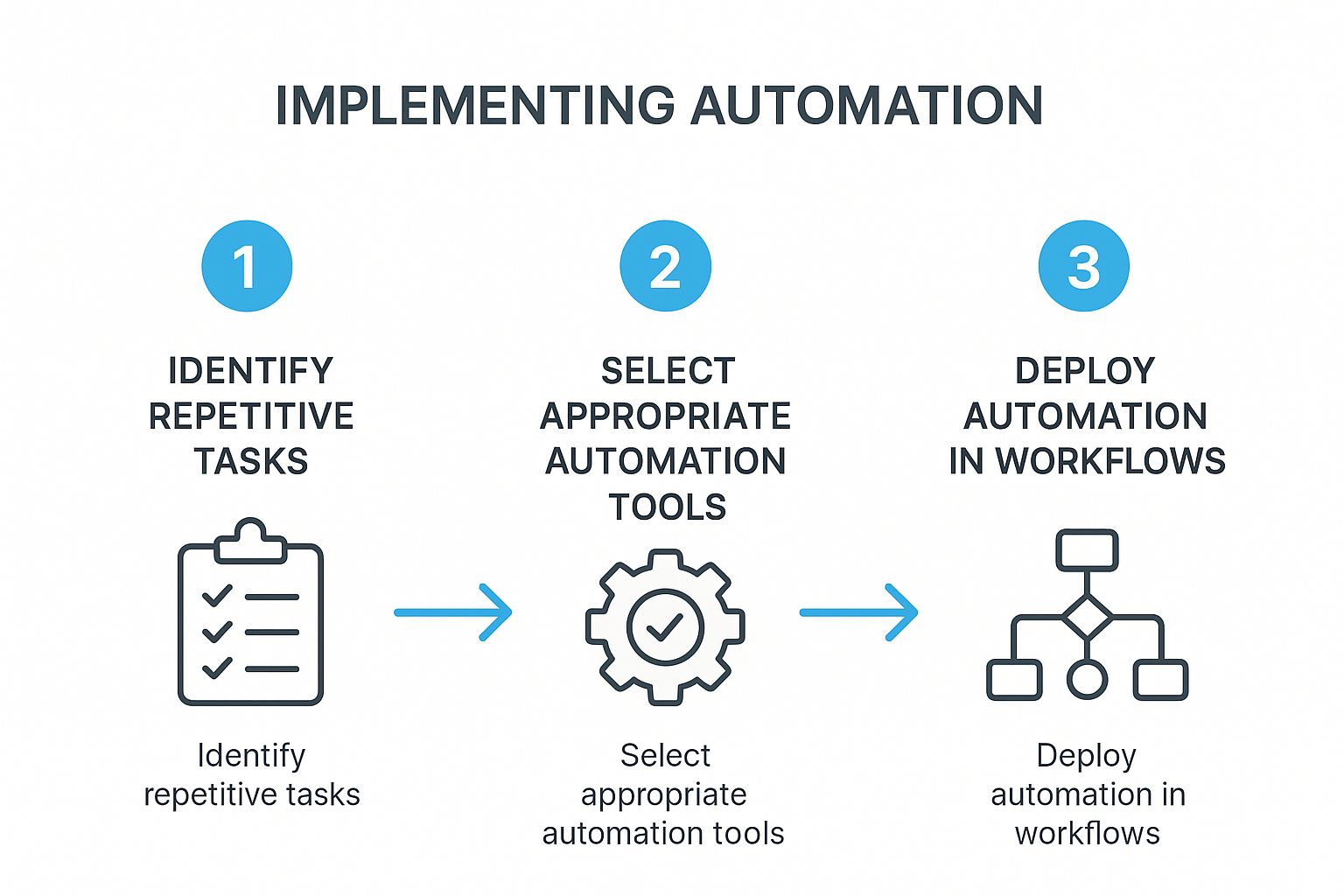

The image below breaks down the basic steps for spotting and acting on these opportunities.

As the visual guide shows, improvement starts with identifying those repetitive tasks, then finding the right tools and fitting them into your existing workflows.

From Visualization to Actionable Improvement

Once your process is mapped out, get your team together to analyze it. Ask the tough questions: Where do tasks get stuck? Are there steps that could be simplified, combined, or eliminated?

Often, the biggest wins come from fixing minor issues. For instance, a modern visitor management system for offices can wipe out manual data entry, automate host notifications, and create a seamless first impression, solving multiple small bottlenecks at once.

By identifying these pain points visually, you can prioritize changes that will deliver the biggest impact. This structured approach moves you beyond just "feeling" inefficient and toward making targeted improvements that boost both productivity and morale.

Let Smart Automation Empower Your Team

Automation isn’t about replacing employees; it’s about unleashing their potential.

To boost operational efficiency, you must automate the repetitive, rule-based tasks that consume your team's time and energy. Think of the hours sunk into manual data entry, processing invoices, or sending routine follow-up emails.

These jobs are necessary but don't add strategic value. They are perfect candidates for automation. The true benefit isn't just speed; it's freedom.

When your team is freed from monotonous work, they can dedicate their brainpower to what people do best: solving complex problems, innovating, and building genuine customer relationships.

Shifting Focus From Repetitive Tasks To High-Value Work

One of the first benefits of automation is a huge drop in human error. Automated systems perform repetitive tasks with near-perfect accuracy, which means less time spent fixing mistakes and more time focusing on proactive work.

The result is a more engaged and motivated team. When people feel their time is used for meaningful work, job satisfaction soars. This directly impacts your bottom line by boosting productivity and cutting costly employee turnover.

The core idea behind smart automation is simple: give your team back their most valuable resource—time. By automating the mundane, you empower them to focus on the strategic initiatives that actually drive business growth.

Practical Automation That Delivers Immediate Benefits

Getting started doesn't require a massive system overhaul. Automation is a key driver for improving operational efficiency, and as noted in these operational efficiency trends over at sdocs.com, many companies are now using low-code tools to automate tasks with minimal effort.

Here are a few areas where automation delivers clear benefits right away:

- Financial Processes: Automate invoice generation and payment reminders to ensure consistent cash flow and reduce the administrative load on your finance team.

- Customer Support: Use automated responses for common questions, freeing up support agents to handle complex issues that need a human touch.

- Data Management: Set up workflows to automatically sync data between apps, eliminating manual exporting and importing of CSV files.

These small changes add up over time, creating a more efficient environment where your team can thrive.

Visitor Management: A Prime Example of Smart Automation

A perfect, real-world example of automation's power is a modern visitor management system. The traditional front desk is a hub of manual tasks ripe for an upgrade.

A digital system like VisitUs automates the entire visitor workflow. Guests can pre-register before they arrive, and check-in is completed with a quick QR code scan.

This single action triggers a chain of automated benefits:

- Instant Host Notifications: The moment a guest checks in, their host gets an automatic alert via SMS, email, or Microsoft Teams. No more hunting people down.

- Automated Badge Printing: Professional visitor badges are printed on the spot, improving security and creating a polished impression without extra work.

- Streamlined Safety Inductions: Important safety information and required legal documents are presented and signed digitally during check-in, ensuring compliance without messy paperwork.

This automation drastically cuts visitor wait times, creating an exceptional first impression. More importantly, it frees your front-desk staff from mundane admin duties, allowing them to focus on higher-value interactions. It's a powerful and practical step toward greater operational efficiency.

Track Performance Metrics That Truly Matter

You can't improve what you don't measure. But tracking data isn't enough—you have to measure the right things. Too many businesses chase "vanity metrics" that look impressive but reveal nothing about their operational health.

To gain real operational efficiency, you must focus on Key Performance Indicators (KPIs) directly linked to your core processes. This data-driven mindset separates guesswork from targeted, high-impact initiatives.

Moving Beyond Vanity Metrics

It’s easy to get distracted by numbers like website traffic or social media followers. While useful for marketing, they don't show how well your internal engine is running. Actionable operational metrics dig into the speed, cost, and quality of your day-to-day workflows.

For instance, a logistics company, instead of just celebrating total packages shipped, could focus on "Order Fulfillment Cycle Time." This specific KPI measures the journey from a customer's click to the package's arrival. Focusing on this metric helps them instantly spot bottlenecks and make changes that customers will actually notice.

The goal is to choose KPIs that act as a compass for your team, guiding their daily decisions and highlighting where their efforts will have the most significant impact.

Key KPIs for Operational Health

To get started, focus on a few metrics that reveal the true performance of your most important workflows. These indicators help you understand not just what you produced, but how efficiently you produced it.

Here are a few essential KPIs to consider:

- Process Cycle Time: The total time it takes to complete a process from start to finish. A shorter cycle time directly signals a more efficient workflow.

- Throughput: The amount of work completed within a specific timeframe (e.g., tickets closed per day). Increasing throughput without adding resources is a huge efficiency win.

- Error Rate: The percentage of outcomes that have mistakes or need to be redone. A high error rate is a red flag for a broken process step.

Beyond general performance, boosting growth with key user retention metrics can also uncover operational weaknesses, as customer churn often points to friction in service delivery.

Actionable KPIs for Operational Health

This table breaks down a few key metrics, what they reveal about your business, and which teams benefit most from tracking them.

| KPI | What It Measures | Most Valuable For |

|---|---|---|

| Process Cycle Time | The total time from the start to the end of a process. | Manufacturing, Logistics, Software Development |

| Throughput | The number of units processed or tasks completed per unit of time. | Customer Support, Production Lines, Content Creation |

| Error Rate | The percentage of outputs that have defects or require correction. | Data Entry, Quality Assurance, Financial Processing |

| Resource Utilization | The percentage of available time a resource is actively working. | Professional Services, Consulting, Project Management |

By tracking the right KPIs, you can move from making assumptions to making informed, strategic decisions that drive real results.

The Power of Visual Dashboards

Collecting data is only half the battle. To make your metrics effective, present them in a way that’s simple, visual, and accessible to your entire team.

This is where dashboards are a game-changer.

A well-designed dashboard turns complex data into easy-to-read charts. This allows team members to see their progress in real-time and understand how their work contributes to the bigger picture. When people see the immediate impact of their efforts, they become more engaged and motivated to find new ways to improve.

For example, a visitor management system like VisitUs provides a dashboard showing visitor traffic, peak check-in times, and average wait times. This data helps facility managers optimize front-desk staffing, which directly improves the visitor experience.

Seeing how technology can transform your business through clear data is a critical step. Ultimately, making performance visible empowers your team to take ownership and drive continuous improvement.

Build Sustainable Practices for Long-Term Gains

Operational efficiency and sustainable business practices are no longer separate goals. Today, they are two sides of the same coin.

Companies are discovering that adopting environmentally and socially responsible strategies often makes their operations leaner, faster, and more cost-effective.

By focusing on reducing waste, conserving resources, and making socially conscious choices, you directly tackle common sources of operational drag. The gains from this approach go beyond a positive public image—they strengthen your bottom line and build a more resilient business.

The Link Between Sustainability and Efficiency

Adopting ESG (Environmental, Social, and Governance) principles is an exercise in optimization. It forces you to look closely at every part of your operation, from energy consumption to supply chain logistics, and hunt for ways to cut waste.

Think about a logistics company that re-evaluates its delivery routes to lower its carbon footprint. The outcome is a more efficient route network that also slashes fuel costs, reduces vehicle wear and tear, and shortens delivery times—a direct boost to performance and customer satisfaction.

A focus on sustainability inherently drives efficiency. When you aim to use fewer resources—be it energy, paper, or time—you are naturally eliminating waste and streamlining the processes that consume them.

By 2025, circular economy models—which emphasize reuse and waste reduction—are offering real financial advantages. As detailed in these 2025 business trends on quantive.com, forward-thinking companies are already using sustainable practices to achieve their efficiency goals.

Practical Steps to Merge Sustainability with Operations

You don't need a complete overhaul to integrate sustainable practices. Small, targeted changes can have a huge ripple effect.

Here are a few tangible ideas:

- Go Digital-First: Ditch paper-based workflows for internal memos, reports, and customer invoices. You’ll reduce paper waste and speed up the flow of information.

- Optimize Energy Use: Run an energy audit to identify waste. Simple changes like switching to LED lighting or installing smart thermostats can lead to massive cost savings.

- Rethink Your Supply Chain: Evaluate your suppliers. A shorter, more local supply chain can cut transportation costs and carbon emissions while minimizing disruptions.

These aren't just "green" initiatives. They're smart business decisions that trim operational fat and make your company more agile.

Visitor Management as a Sustainability Driver

A perfect example of this synergy is a modern visitor management system. The old-school front desk, with its paper sign-in books, is a major source of waste and inefficiency.

Switching to a digital solution provides immediate, measurable benefits for both sustainability and efficiency. You can improve efficiency with a visitor sign-in system in several ways. Eliminating paper logs reduces waste and creates a more secure, streamlined, and eco-friendly reception area.

This one change gets rid of manual data entry, automates host notifications, and ensures compliance information is handled digitally. The result is a faster, more secure check-in process that uses fewer resources and frees up staff time—a perfect example of how sustainable practices drive real operational gains.

Common Questions About Operational Efficiency

Even with a clear strategy, the journey to improve operational efficiency can raise many questions. Here are answers to some of the most common ones.

Where Is the Best Place to Start?

It's tempting to overhaul everything at once, but that's a recipe for burnout. The best approach is to start small. Target a single, high-impact process that is a known source of frustration.

Think about client onboarding or invoice approvals. These workflows are often tangled in manual steps. One study found that the average office worker is only productive for about three hours a day, with clunky processes being a major culprit.

By mapping just one of these workflows, you can pinpoint the main bottleneck and apply a focused fix, like simple automation. This gives you a quick win—which is great for morale—and builds momentum for bigger improvements.

How Can Technology Help Without a Huge Investment?

Boosting efficiency doesn’t require a massive tech budget. The secret is to focus on scalable Software-as-a-Service (SaaS) tools with flexible subscription models, avoiding large upfront costs.

Modern solutions for project management, team communication, or visitor management deliver powerful results without breaking the bank. For instance, a visitor management system offers an immediate return by automating front-desk tasks, which can save administrative staff up to 95% of the time they spent on manual check-ins. You can explore more of the benefits of a visitor management system to see how this tech drives real value.

A common mistake is thinking efficiency requires a complete tech overhaul. Often, the smartest move is to adopt affordable, specialized tools that solve one specific problem exceptionally well, creating a ripple effect of positive change.

How Do I Get My Team on Board with Changes?

For any operational shift to stick, team buy-in is essential. The most critical step is to frame changes as a way to eliminate tedious work, not just a top-down order to cut costs.

Involve your employees from the start, especially in process mapping. They are the experts on day-to-day workflows and will offer insights leadership might miss. When you give them a voice in designing the solution, they become invested in its success.

Always communicate the "why" behind every change. Explain how a new tool or process will make their daily work less frustrating. Finally, celebrate early wins publicly. When the team sees tangible proof that the new way is better, they'll become your strongest advocates.

What Is the Difference Between Efficiency and Productivity?

These two terms are often used interchangeably, but they measure very different things.

- Productivity is about output. It’s a measure of volume—like the number of support tickets your team closes in a day.

- Efficiency measures the resources you used to achieve that output. It's a measure of input—the time, money, and effort it took.

Here's a simple way to think about it: you can be highly productive but incredibly inefficient. Imagine two teams both close 100 support tickets. If one team does it with five people and the other needs ten, the first team is far more efficient. The goal isn't just to work harder, but to work smarter. For a deeper look, check out this comprehensive guide on how to improve operational efficiency.